For generations, online bronze has been used to cast sculptures and other artefacts. Previously, a worker would work on a clay casting, which was then used to manufacture bronze castings out of liquid bronze. The casting would be shattered after the bronze had set, and the new bronze object would be finished. There are several advantages to employing the bronze casting method. Continue reading to learn more.

Bronze is reasonably priced.

Bronze is substantially less expensive to purchase than gold or silver. This means you may make larger sculptures and works of art without worrying about the expense. Interestingly, if you are dissatisfied with the results of your casting, bronze may be readily melted down and reused. You will not have to worry further about expense of lost resources whether any of the bronze is damaged during the audition process.

Bronze is a relatively pliable metal.

Because Online bronze is a more pliable substance, you may continue working on your cast after the liquid metal has cooled. For example, you could want to cast a basic outline for an architecture that you can subsequently modify by making fine modifications to the design and surfaces of the metal. Because of the malleability of the aluminium, you can quickly restore a broken bronze item.

Bronze is a very long-lasting substance.

Bronze is a very long-lasting substance. Bronze castings in pristine condition have been discovered from ancient locations. Bronze is not corroded by chemicals, UV radiation, or other environmental variables. Bronze exceeds iron and copper in terms of strength, which implies because whatever you cast in brass will last a long time.

When smoothed, bronze looks stunning. Resistant to Corrosion

One of the reasons Online bronze statues remain so long is their resistance to corrosion. If you are creating a work of art or a piece of equipment that will be used outside or in a typically corrosive atmosphere, you may appreciate this property of bronze. Keep in mind that bronze cast sculptures may be left outside in direct sunlight for years without deterioration. Several other materials are not the same. If you want to learn more about the advantages of working with bronze or request a bronze statue, you should ask a professional firm that can supply you with bronze effected.

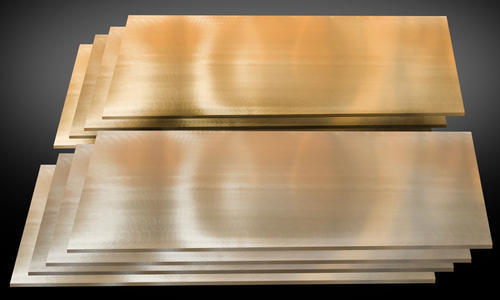

High resistance to Friction

Of all, bronze casting isn’t solely for decorative purposes. Its qualities also make it suitable for a wide range of industrial applications. For example, a machine part made of bronze can resist the friction of being in a mechanism with other materials. It can also withstand extended access to other elements instead of being harmed. To prevent wasting a lot of materials, draw the contour of the object you’ll be moulding using a pencil first. This way, if you make a mistake, you may quickly remove it.

Another wonderful advice for using bronze is to first and foremost get your supply from a reliable supplier. You’ll need a consistent supply of bronze materials, especially if you’re working on a collection.

Yet even with being surpassed by metal in a variety of building components activities, bronze retains a position in a few of them. Many moveable bridge elements, cordless circular wheels, and bridge turntables, for example, are constructed of a specific variety of bronze. A form of bronze is also used in modern safety equipment such as hammers, tennis rackets, and fasteners. These implements were originally made of metal, but due to the risk of fire hazard caused by the dangerous sparks produced by steel, steel was substituted with Online bronze.

Because of its strong electrical conductivity, heat resistance, and low friction qualities, bronze is ideal for a variety of machine parts, including spur gears, bushings, bearings, valve components, and even valve guides in aviation engines. There aren’t many metals that have low friction, which is important in situations where parts are constantly sliding against itself. We assume you currently understand your way through bronze now that you should have at least a basic expertise of it and want to use it for any future work. Of addition, the effectiveness of those undertakings is also dependent on the size of the bronze materials used.